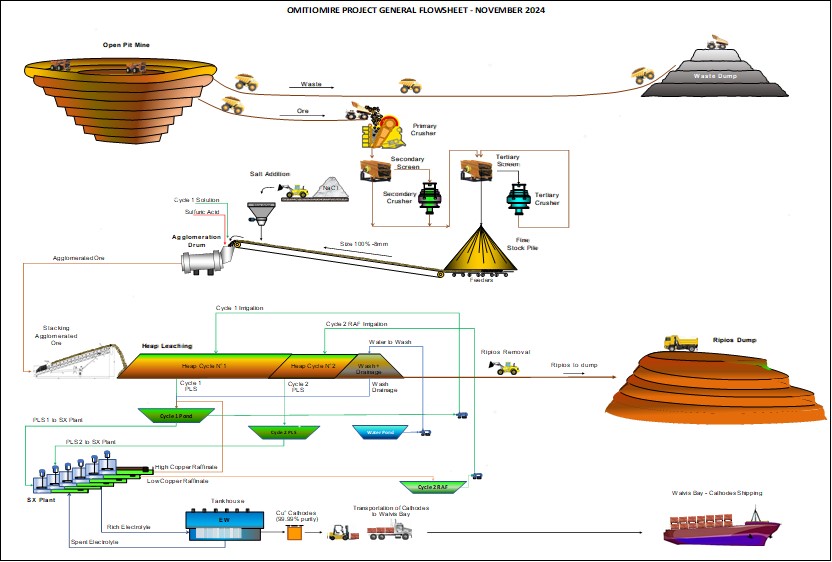

Based on the positive results of the initial metallurgical test work programme in 2021, and mineralogical investigation, metallurgical consultants MJO Ingeniería y Consultores en Metalurgia SpA (MJO), Chile, have developed a number of metallurgical test work programmes designed to demonstrate that the Omitiomire chalcocite mineralisation is amenable to processing by chloride-curing, acid heap leach and Solvent Extraction/ Electro-Winning technology (SX/EW).

The SX/EW processing method accounts for 20% of worldwide copper production and is used to good effect in the arid regions of North America, Chile, Peru, and China.

Benefits of SX/EW:

- cost effective

- low-impact

- low water consumption

- high-purity cathode

The company has undertaken 4 phases of metallurgical test work over 3 years resulting in a robust metallurgical recovery process for the Omitiomire Copper Project. This comprehensive programme has included 25 full-size heap leach columns, 35 mini-columns, extensive mineralogical investigations and process simulations to demonstrate the viability of using a high-Cu low-acid leach solution, along with the chloride leaching process, to successfully recover the copper at Omitiomire.

Phase 2 of the metallurgical test work programme, using full-height columns, demonstrated that 77% Cu recovery with 44kg/t acid consumption and a 300 day leach cycle was achievable using standard chloride and sulphuric acid leach. However, it was noted in this test work that nearly all the acid was consumed in the first metre of the column, while maintaining over 70% copper recovery in the subsequent metres. This lead to the development of the next phase of test work to develop a concept of high-Cu and low-acid solution in the leaching process.

The Phase 3 metallurgical test work, using three mini-columns, demonstrated the technical feasibility of using a high-Cu low-acid leach solution to significant reduce the acid consumption to 10-15kg/t and reduce the leach time to estimated 200 days, while also increasing the recovery to 80%.

Phase 4 test work, was designed to develop the process further to BFS level of confidence with 11x full-height columns testing various leach conditions to optimise recovery, acid consumption and leach time. The chalcocite portion of the mineralisation represents approximately 90% of the contained copper. The remaining copper oxide minerals are readily leached in dilute sulphuric acid alone.